In 2023 it’s easy to wonder who invented plastic, and if the world would have been better off if they hadn’t. Plastic is responsible for a tremendous amount of damage to our natural world and to ourselves. But that wasn’t always the case.

The development of plastic was a major advancement in materials science and included contributions from thousands and thousands of scientists. Some are names you’re familiar with and some aren’t. In this article we’re going to cover the who, when, why, and how of the creation of plastics.

The Origins of Plastic

Plastic is a material made up of organic or synthetic compounds that have the property of being malleable and therefore can be molded into solid objects of various shapes. This property gives plastics a wide variety of applications. Its name derives from plasticity, a property of materials, which refers to the ability to deform without breaking.

The history of plastic dates back to the mid-19th century when early versions of plastic-like materials, such as natural rubber and celluloid, were developed. However, it was not until the early 20th century that modern plastic was invented.

Vulcanized Rubber – Invented by Goodyear (and Hancock?)

One of the first pliable, moldable materials that would hold its shape was rubber – specifically, vulcanized rubber. Rubber naturally is a tacky, gummy substance that comes from processing the latex liquid extracted from a rubber tree. This natural rubber was useful for many purposes, including early tires. However, it wasn’t durable enough, especially when warmed.

American inventor Charles Goodyear spent much of the 1830s experimenting to discover a way to make it more stable. In the late 1830’s he accidentally discovered that heating it would help to solidify it, and named the process “vulcanization”. A few years later in 1843, he filed a patent for that process. You may remember from your Greek and Roman mythology that Vulcan is the god of fire and the forge! An appropriate name.

Across the pond in England, Thomas Hancock was an inventor working with rubber at about the same time. He had early success by devising a method for recycling rubber scraps to avoid the large amount of waste inherent in manufacturing various products from rubber. Our kind of guy! Hancock applied for a patent at the British patent office for vulcanized rubber only 8 weeks after Goodyear did so in the US. He claimed he discovered the use of sulphur for this purpose on his own, and had heard the name from someone else – purely coincidentally. I don’t buy it! It appears he had gotten his hands on a sample of Goodyear’s vulcanized rubber, and was able to reverse-engineer it.

Parkesine – Invented by Alexander Parkes

In 1856, Alexander Parkes, an English inventor, developed the first plastic, which he called Parkesine. Parkesine was made by dissolving cellulose in a solvent and then hardening it by removing the solvent. It was an improvement over earlier plastic-like materials, as it was stronger and more durable.

Parkesine was the first form of Celluloid, which can be considered the predecessor of the first synthetic plastic. It is made by dissolving nitrocellulose, a highly flammable substance, in a mixture of camphor and alcohol. Celluloid was initially used as a substitute for ivory in the production of billiard balls, but it was also used in a variety of other applications, including as a film base for early motion pictures and as a material for making combs, buttons, and other small items. While celluloid was an important precursor to modern plastics, it has largely been replaced by safer and more durable materials.

The Invention of Plastic

The early forms of natural plastic materials were extremely useful but there was one problem. Industrialization soon caused the world to exhaust the world’s supply of natural rubber. The human story doesn’t change much, does it? We use up everything we can until there’s no more! Once we’ve run out of natural substances we look for artificial replacements.

The demand for these new materials was so intense that it led to the pursuit of a fully-synthetic plastic that wouldn’t require natural materials at all.

Bakelite – Invented by Leo Baekeland, the “Father of Plastic”

If we have to give a single answer to the question “who invented plastic”, it must surely be Leo Baekeland. In 1907, this Belgian chemist created Bakelite, the first fully synthetic plastic. Unlike its predecessors, Bakelite wasn’t made from natural materials like cellulose, but rather from phenol and formaldehyde. This revolutionary material was moldable, heat-resistant, and an excellent insulator, making it perfect for a wide range of applications, from electrical components to fashion accessories.

Bakelite’s success laid the foundation for the modern plastic industry, and Baekeland’s work earned him a well-deserved place in history.

So, how did the invention of plastic change the world? Well, for starters, it completely transformed manufacturing, providing a lightweight, durable, and cost-effective alternative to traditional materials like wood, glass, and metal. Plastic has since become an integral part of our daily lives, showing up in everything from packaging to cars and electronics.

Modern Plastics Development

Let’s continue our journey through the world of plastic and explore how it’s evolved over the years to become the ubiquitous material we know and love (and hate) today. From the early days of Bakelite to the wide variety of plastics that surround us now, there’s a lot to discover about this incredibly versatile material. So, let’s dive in and see how modern plastic production has developed and adapted to our ever-changing needs!

After Bakelite’s massive success, scientists and chemists began to develop a whole range of new plastics, each with its own unique properties and applications.

Polystyrene (PS)

Around the same time that Goodyear and Hancock were developing the rubber vulcanization process, polystyrene was first accidentally synthesized by German apothecary Eduard Simon in 1839. Polystyrene gained commercial popularity in the 1930s thanks to the Dow Chemical Company’s development of an expandable version known as Styrofoam. Its lightweight and insulating properties make it popular for food packaging and disposable coffee cups, but it’s notoriously difficult to recycle. Many municipalities around the world are exploring polystyrene bans, and I support it wholeheartedly.

Polyvinyl Chloride (PVC)

When you hear “PVC”, you’re almost certainly thinking of the white plastic pipe. First synthesized in 1872 by German chemist Eugen Baumann, PVC really took off in the 1920s when Waldo Semon, a researcher at B.F. Goodrich Company in the US, made it more flexible and easier to process. Its resistance to chemicals and electrical conductivity make it popular for construction materials and electrical cables.

PE (Polyethylene)

One of the most popular plastics we use today, polyethylene, was also discovered by accident in 1933 by two British chemists, Reginald Gibson and Eric Fawcett. This lightweight, flexible, and chemically resistant plastic quickly gained popularity and is now used in countless plastic products, from grocery bags and food packaging to water pipes and medical equipment. Polyethylene comes in two forms: High-density (HDPE) and Low-density (LDPE)

HDPE was developed in the 1950s by German chemist Karl Ziegler and Italian chemist Giulio Natta. It is celebrated for its versatility and durability. From detergent bottles to toys and even pipes, this plastic is widely used and easy to recycle (which we love).

Another product of Ziegler and Natta’s work in the 1950s, LDPE is known for its flexibility and low cost. Often used for plastic bags, cling wrap, and squeeze bottles, this plastic is more challenging to recycle than HDPE and PET.

Ziegler and Natta ultimately won the Nobel Pize in Chemistry in 1963 for their contributions to polymer science.

PET (Polyethylene Terephthalate)

Invented in 1941 by British chemists John Rex Whinfield and James Tennant Dickson while working at the Calico Printers’ Association in the UK, PET is known for its strength, flexibility, and transparency. Commonly used for water bottles and food packaging, this plastic is lightweight and recyclable.

PP (Polypropylene)

Invented in 1954 by Giulio Natta while working at the Montecatini company in Italy, PP is appreciated for its resistance to heat, chemicals, and moisture. It’s commonly used for yogurt containers, bottle caps, and straws, and is increasingly being accepted in plastic recycling programs.

Other (Various)

This category includes a wide range of less-common plastics, such as polycarbonate (PC), invented by Daniel Fox at General Electric in the US in the 1950s, and used for eyeglasses and electronic devices, as well as biodegradable plastics and other specialty materials. Recycling these plastics is often more challenging due to their diverse composition.

Plastic Production Techniques

As the variety of plastics grew, so too did the techniques for producing them. In the early days of plastic production, methods like compression molding, where plastic is heated and pressed into a mold, were the norm. However, as plastics became more diverse and demand increased, manufacturers began to explore new, more efficient production techniques.

Injection Molding

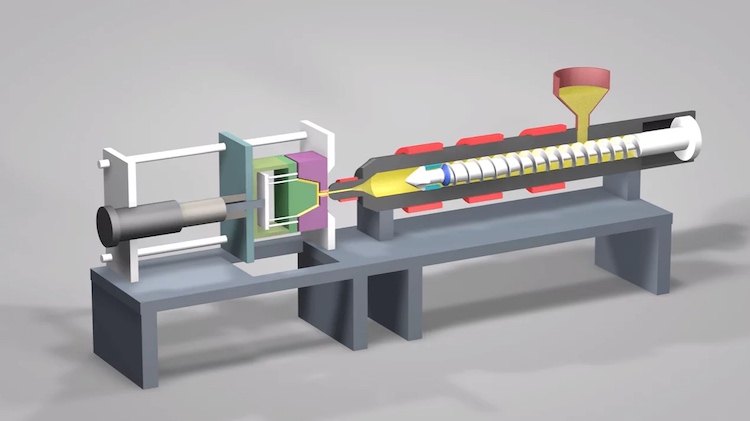

Enter injection molding, a game-changing process invented by James Watson Hendry in the late 1940s. This method involves melting plastic pellets and injecting the molten material into a mold under high pressure. Not only is injection molding faster than traditional methods, but it also allows for more intricate shapes and designs, making it the go-to technique for producing everything from toys to automotive parts.

Blow Molding

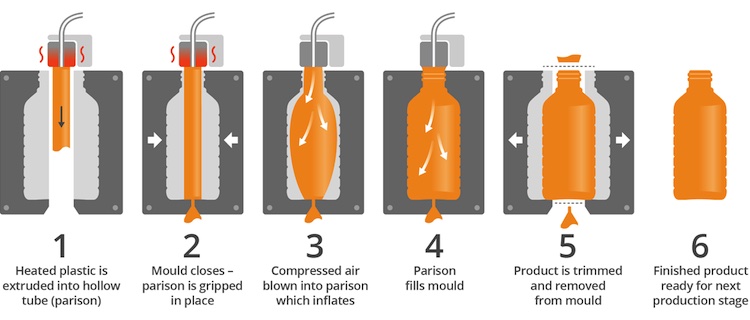

Another major leap in plastic production came with the development of blow molding in the late 1950s. This process, which involves inflating a heated plastic tube (called a parison) inside a mold, revolutionized the production of hollow plastic objects like bottles and containers.

Extrusion

And let’s not forget extrusion, a technique that allows manufacturers to create continuous plastic profiles like pipes and sheets by forcing molten plastic through a shaped die.

In conclusion, the transition to modern plastic production has been marked by a series of groundbreaking inventions, each building on the last to create the diverse range of plastics we use today. From polyethylene and PVC to advanced production techniques like injection molding and blow molding, the evolution of plastic has transformed industries and changed the way we live, work, and play.

Environmental Impact of Plastic

Humans have manufactured a total of 8.3 billion tons of plastics, a mass equivalent to almost 160,000 ships like the Titanic. Only 9% of this amount is recycled, while 12% is incinerated and 79% accumulates in landfills. Plastic pollution has become one of the most pressing environmental problems of our time, which calls for intensified efforts not only to recycle but also to reduce its use and replace it with other, more sustainable materials.

So, while we can’t ignore the myriad benefits that plastic has delivered to society, it’s vitally important to recognize the environmental impact of this versatile material. From ocean pollution to its effects on wildlife, plastic has left its mark on our planet in more ways than one. So let’s dive in and explore the not-so-pretty side of plastic and the efforts being made to reduce its environmental footprint.

The Great Pacific Garbage Patch – A floating island of trash

First up, let’s talk about the Great Pacific Garbage Patch. This massive collection of plastic debris, located between Hawaii and California, is a sobering reminder of the consequences of our plastic addiction. Spanning an area twice the size of Texas, the patch is the result of ocean currents concentrating plastic waste from all over the world. The impact on marine life is devastating, as creatures like sea turtles, fish, and seabirds often mistake the plastic for food or become entangled in the debris.

Microplastics – sushi with a side of polymers

And it’s not just the big stuff we need to worry about – microplastics, tiny particles of plastic that break down from larger items, have infiltrated the entire marine ecosystem, making their way into the food chain and even our own bodies. We have only begun to understand the effect of having plastic trapped inside our bodies, and the more we discover the worse it looks.

PFAS – Forever Chemicals

But the problems don’t stop there. Some plastics contain “forever chemicals” like per- and polyfluoroalkyl substances (PFAS), which are highly resistant to breaking down in the environment. These chemicals can accumulate in the ecosystem, posing risks to both wildlife and human health. In humans, we’ve identified negative impacts to the circulatory system, the liver, pregnancy-related problems, and even increased risk of cancer. The widespread use of plastic has made it an environmental challenge that can’t be ignored.